A product or service that falls short of customers’ quality standards becomes irrelevant sooner or later. That’s why Critical to Quality (CTQ) — a key concept in quality management — has become the go-to framework for serious brands that aim to stay competitive and profitable.

Let’s take a dive into some definitions, examples, and applications.

CTQ meaning

Critical to Quality (CTQ) refers to the specific characteristics of a product or service that customers consider essential or non-negotiable. As such, these characteristics directly impact customer satisfaction, and their absence can lead to disappointment, loss of potential revenue, churn, and even product failure.

A business that knows exactly what its customers want, and consistently delivers on those expectations, is the recurring outcome for companies that correctly apply the tools, processes, and principles of CTQ.

Widely used to systematically identify and meet customer needs, CTQ helps organizations deliver superior products and drive business success in a repeatable manner.

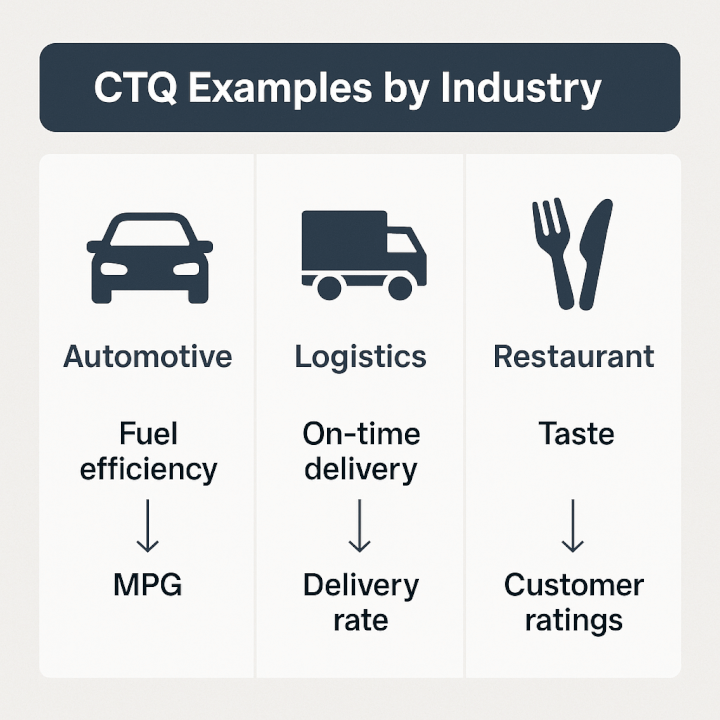

Any measurable attribute that matters most to customers can be considered a CTQ element. Here are two industry-based CTQ examples:

- Fuel efficiency is a common CTQ in car manufacturing, quantified using metrics such as miles per gallon.

- On-time delivery is a key CTQ in the logistics industry, tracked using metrics such as on-time delivery rate, average delivery time, transit time, and order accuracy.

Why are CTQs important?

Often implemented within the Lean Six Sigma methodology, Critical to Quality can help your organization flip the script on many unwanted business results: process inefficiencies, unclear goals, and customer churn. More importantly, CTQ can help you zero in on, prioritize, and sustain the specific characteristics of your product that attract customers and keep them coming back for more.

In essence, CTQs represent the elemental building blocks of quality management. They use data and metrics to translate customer expectations into actionable quality benchmarks. In doing so, CTQs align products with customer needs, helping drive revenue and business growth. By implementing CTQs, your company can focus its improvement initiatives on areas and processes that matter most to your customers.

Here’s how CTQ can benefit your business:

- Achieve high customer satisfaction scores. CTQ helps identify the things that make your customers happy. By delivering those things, you ensure their loyalty and sustained business.

- Guide product design and development. CTQs provide specific customer requirements and preferred quality standards, removing any ambiguity in how the end product or service should be.

- Implement quality assurance. Once established by listening to the customer’s voice, quality standards can be maintained through continuous monitoring and improvement, reducing waste, defects, and errors.

- Improve process efficiencies. By uncovering weaknesses and gaps in a product or service, CTQs help pinpoint the specific areas where process improvement should be carried out.

- Mitigate risk. CTQ can help mitigate risk by focusing on the most important aspects of a product or service ensuring that these are managed effectively.

- Make smarter decisions. CTQs are quantified, measured, and calibrated. As an integral element in the data-driven methodology of Six Sigma, CTQ can help leaders, project owners, and team members make informed decisions about resource allocation, product design, and process optimization.

CTQ characteristics

CTQs have several key characteristics that make them valuable for ensuring the quality of a product or process. These key characteristics include:

- Customer-centric: CTQs reflect the customer’s real needs and expectations, not ungrounded assumptions. To ensure accuracy and authenticity in identifying what truly matters, CTQs are derived using the Voice of the Customer (VoC) process.

- Specific. CTQ elements are specific, clearly defined, and easy to understand. This helps avoid ambiguity and makes it easier to set precise goals and take appropriate actions.

- Measurable. CTQs must be quantifiable. They are defined by metrics that can be compared against standards and benchmarks, making it possible to evaluate their performance objectively and take calibrated actions when needed.

- Actionable. CTQs are linked to processes and systems that can be controlled and improved upon. This makes it possible for organizations to isolate a CTQ and take specific actions that help maintain, restore, improve, or enhance its quality.

- Prioritized. CTQ elements differ in relative importance. Some CTQs are more critical than others. CTQ elements that impact customer satisfaction the most should be the top items on the agenda.

- Business-oriented. CTQs should be aligned with overall business strategy and objectives. It’s easy to trace this ideal alignment: quality standards impact customer satisfaction, which in turn, helps generate revenue. Improved revenues lead to business growth.

How to identify CTQs

Specifying CTQs depends on the industry and target market. For example, a restaurant might consider taste, presentation, price, and ambiance as priority CTQs to ensure the dining experience would consistently delight customers. Meanwhile, a car manufacturer might list reliability, safety features, and fuel efficiency as the CTQs that matter most to its customers.

You can use the following steps to establish the CTQs for your company:

- Voice of the Customer (VoC): Gather feedback from customers through surveys, interviews, and focus groups to understand their needs, priorities, and expectations.

- CTQ Tree: Draw a hierarchical diagram to break down high-level customer requirements into more specific and measurable characteristics (more on this later).

- Prioritization: Rank CTQs based on their impact on customer satisfaction and business performance.

The DMAIC approach is also an excellent way to identify and manage the CTQs of your product or service:

- Define: Identify what is critical to quality from the customer's perspective by accurately identifying their needs and requirements. This could involve gathering customer feedback, conducting surveys, and analyzing customer reviews/ratings of your product.

- Measure: Establish a baseline or quality standard. Measure the current quality performance of the product by collecting data on various process parameters and metrics. Compare the baseline with actual values.

- Analyze: Analyze the collected data to identify the root causes of weaknesses that affect quality.

- Improve: Develop and implement solutions that address the root causes of the problem.

- Control: Set control mechanisms to ensure that improvements are sustained over time.

Understanding CTQ trees

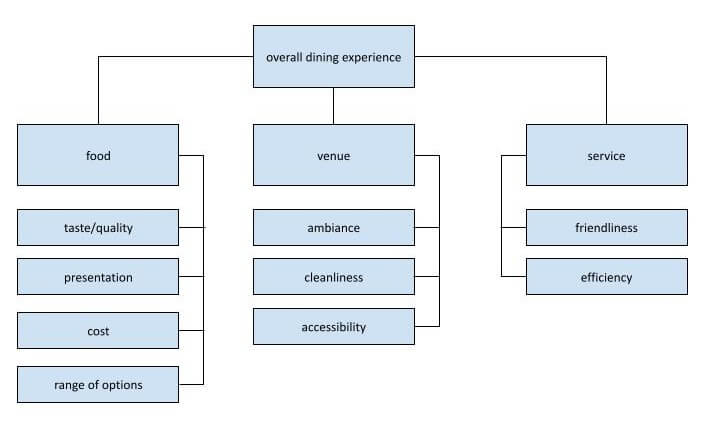

A CTQ tree is a Six Sigma visualization tool you can use to break down CTQs into simpler and more quantifiable components. Often depicted as hierarchical diagrams, a CTQ tree helps enhance the ability of businesses to understand the key characteristics of a product or service that significantly affect customer satisfaction. It starts with a broad customer need and branches out into detailed and actionable components.

Companies can use CTQ trees to identify and address specific quality issues. CTQ trees are powerful tools for visualizing the root causes of quality-related problems and for developing targeted and effective solutions. They can help align every aspect of your product with the desired attributes that truly matter to your customers.

For example, a restaurant’s CTQ tree might look like this:

Key components of CTQ trees:

A CTQ tree consists of three main components:

- Need. This component functions as the top-level identifier, representing the customer’s general need and expectation. Broad in scope, it encapsulates the desired outcome of both the customer and the business.

- Driver. This component refers to the specific attributes or characteristics of a product or service that directly impact customers’ perception and assessment of quality. Customers use drivers to evaluate whether their need is being met by a service or product.

- Requirements. These are detailed specifications and quantified standards against which the specific drivers are being measured as reflected in customers’ satisfaction level. Businesses can use them to set performance targets and quality benchmarks.

Here’s an example to illustrate each of the components:

- Need: reliable daily transport vehicle

- Drivers: fuel efficiency, safety, comfort, performance

- Requirements: fuel economy (mpg), official industry safety ratings, ergonomic seats, acceleration (time it takes to go from 0 to 60 mph), etc.

How to create a CTQ Tree

A CTQ tree is a visual tool that helps break down broad customer requirements into specific, measurable elements. Creating one is a simple, straightforward task.

Imagine a hierarchical diagram similar to a family tree. Each top-level element (need) is defined in detail by one or more critical quality characteristics (drivers) that affect customer satisfaction. Meanwhile, drivers are translated into measurable product specifications (requirements) that allow companies to deliver the specific quality characteristics customers want.

To create a CTQ tree, here are the key steps to take:

- Determine need. What customer need are you addressing with the product or service?

- Identify at least three drivers. What specific attributes or characteristics (related to the need) will your customers consider when assessing the quality of your product?

- Establish the required specifications. What are the actionable benchmarks that can help you meet customer standards for each driver?

Want to learn more about the Lean Six Sigma methodology?

Check out this ebook that will guide you through the key concepts of LSS.

How to master CTQ and transform your business

Applied correctly, CTQ principles and techniques can transform a business. Manufacturing companies can use CTQs to reduce defects and increase production efficiency. Healthcare organizations can leverage CTQs to improve treatment outcomes and the accuracy of diagnoses. Service industries can identify the drivers that help reduce wait times and enhance customer satisfaction.

Any professional can get better at using CTQs to drive positive change in their organization. One of the best ways to do so is to become a Lean Six Sigma (LSS) practitioner. After all, CTQ is a concept native to the data-driven methodology of Six Sigma.

Lean Six Sigma provides a structured approach to identifying and leveraging CTQ elements to squarely align your company’s product line and solutions with the expectations of your customers.

The entry-level rank in Lean Six Sigma (Yellow Belt) will equip you with the skills to correctly apply Critical to Quality principles. A Black Belt will help you master all the LSS fundamentals including CTQ. By becoming an LSS practitioner, you will gain the specialized skills to

- Determine CTQs using approaches such as VoC.

- Break down processes and products into simpler steps and components.

- Identify and prioritize areas for improvement.

- Develop and implement effective solutions to quality-related problems.

Find success by focusing on quality

To say that ‘quality is critical’ is not only an understatement. It’s also insufficient to change anything.

However, taking action using Critical to Quality can do far more. CTQ strengthens the link between what your company offers and what your customers need. It helps you match the must-haves in their checklist with the features and specs of your product.

Everybody knows what happens when every checkbox gets ticked: customers get happier, profits get healthier, and business gets primed to achieve the next milestone.

Why wait to get the ball rolling? You can start now by learning more about CTQ and how to play it like a pro.

Prepare to get certified in Lean Six Sigma

Start learning today with GoSkills courses

Start free trial